Reduce costs bit by bit and increase benefits every minute

Adopt HAMMETT precision ceramic quantitative cylinder system

Energy-saving and consumption-reducing, boosting green and high-quality development system

Photovoltaic

New energy

Communication

Industrial

Select polymer materials

with higher cost

with smoother surface

with higher wear resistance

View details

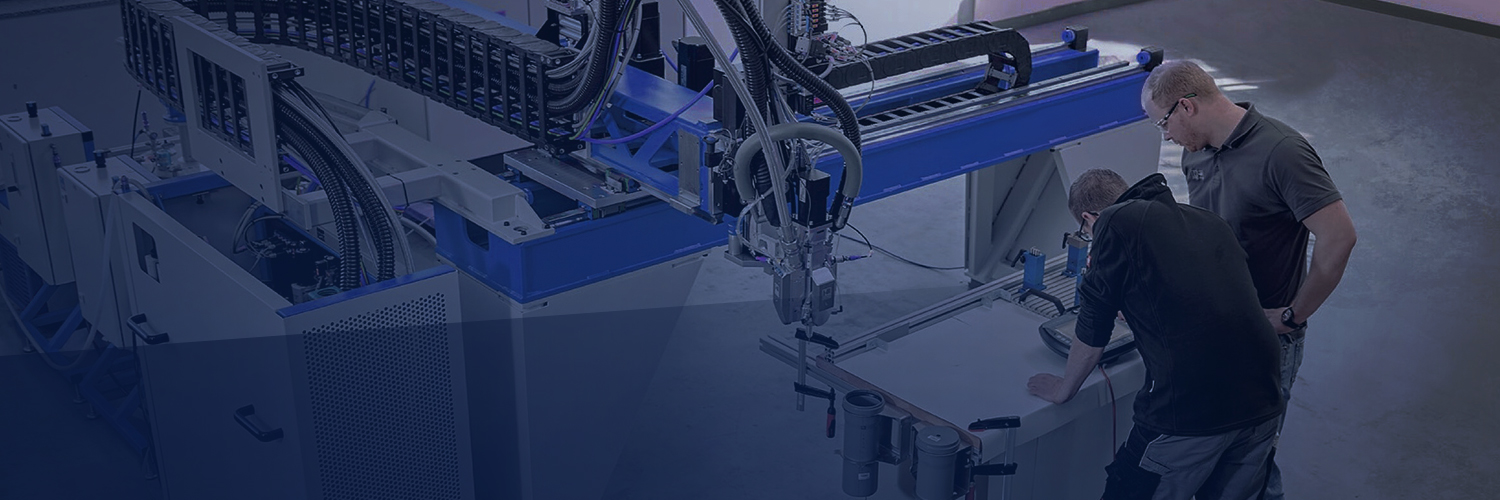

Using Hammett precision ceramic quantitative cylinder system

to dock with MES can realize three-dimensional space path dispensing

precise positioning and control of glue, glue valve suction, no wire drawing, no glue leakage dispensing and gluing

View details

Mature expert team

private customized solutions

professional equipment commissioning

complete after-sales service

View detailsCOPYRIGHT © 2023 Shanghai Shengpu Fluid Equipment Co., Ltd .AL RIGHT RESERVED.